Bi-Stable Rotary Solenoids

Product introduction

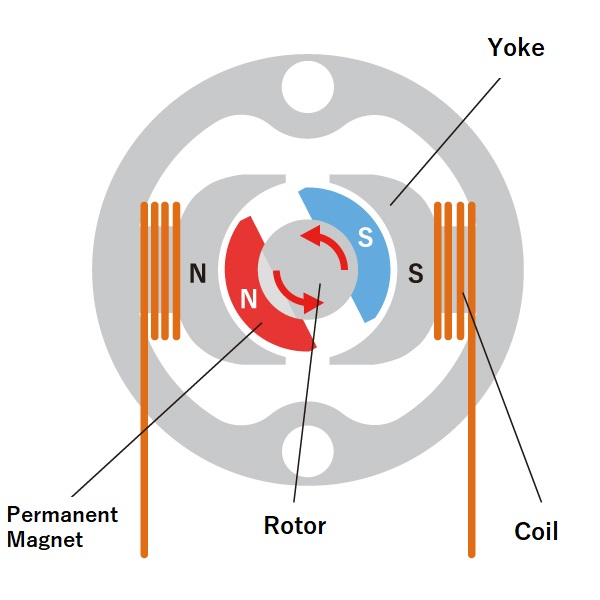

Takano’s rotary solenoids use cylindrical permanent magnet as the rotor and produce true rotational motion from the repulsive and attractive forces induced between the permanent magnet and the magnetic poles in the yoke. Even after de-energization, the solenoids stay in position using the holding force of the permanent magnet. Unlike conventional rotary solenoids built to mechanically convert the back-and-forth linear motion (thrust-direction motion) of the shaft into rotational motion, our rotary solenoids produce rotational motion with no axial movement of the shaft and hence have a longer life.

-

It's bi-stable

Bi-stable type switches clockwise and counterclockwise rotation every time the current direction is changed between +(positive) and –(negative). Even after de-energization, the solenoid stays in its position using the holding force of the permanent magnet. Unlike the rotary solenoids that use a spring for the motion of one direction, bi-stable solenoid rotate in both directions by magnetic force and current pulse.

-

High power and fast response

It is high power and quick response because this solenoid reciprocates by the change of current direction, +(positive) and –(negative), instead of using spring.

-

Flexibility in travel angle up to 90°

Travel angle can be set up to 90° depending on your application requirement.(Requires external stops. See How to set external stops for details. )

-

Extremely silent

There is no axial motion of the shaft in thrust direction and the end stops are set externally. This leads to minimizing the impact noise when in operation. For types with internal end stops, countermeasures are taken for impact and vibration by carefully choosing the buffer used for the stops.

-

Long Life

Long life because of no sliding parts except for the bearing.

-

Return-by-spring type is also available

Self-restoring types using spring return are also available, enabling a fail-safe capability.

Series Comparative Table

Flat type Rotary solenoidsRSF22 Series

- The slimmest(8mm) type in the series. This model is suitable for installation in narrow limited space.

- Higher in torque compared to motors in similar shape.

- Thin rotary solenoids ideal for high-speed shutters for optical equipment.

Applications

- High-speed shutters for optical equipment.

- Fundus camera, Surveying equipment, Microscope

| Model | Dimension(㎜) | DC resistance | Peak Torque(N・m) | Documents/Drawings | ||

|---|---|---|---|---|---|---|

| 5V | 12V | 24V | ||||

| RSF22/08-O035 | φ22×8 | 35Ω | 0.0017 | - | - | |

Flat type Rotary solenoidsRSR28 Series

- This model is suitable for installation in narrow limited space.

- No axial stroke and high durability

- Suitable for mechanical in/out of optical parts (filters and lenses) and for use in shutters.

Applications

- High-speed shutters for optical equipment.

- Excimer Laser System, Fundus camera, Surveying equipment, Microscope

| Model | Dimension(㎜) | DC resistance | Peak Torque(N・m) | Documents/Drawings | ||

|---|---|---|---|---|---|---|

| 5V | 12V | 24V | ||||

| RSR28/17-CAB0 | φ28×17 | 8Ω | 0.013 | 0.024 | - | |

Micro type Rotary solenoidsRSR7 Series

- Micro rotary solenoid designed as a mechanical drive for compact equipment with limited space inside.

- Approximately one-quarter in size (volume) compared to our first micro model, RSR10/15.

- Ideal for high-speed shutters of optical systems.

Applications

- High-speed shutters for optical equipment.

- Optical switch, Infrared Cameras, Thermal Imaging Cameras

| Model | Dimension(㎜) | DC resistance | Peak Torque(N・m) | Documents/Drawings | ||

|---|---|---|---|---|---|---|

| 5VDC | 12VDC | 24VDC | ||||

| RSR7/10-T010 | φ7×10 | 9.5Ω | 0.00045 | - | - | |

Micro type Rotary solenoidsRSR10 Series

- Micro rotary solenoid designed as a mechanical drive for small equipment with limited space inside.

- High-speed shutters for optical equipment.

Applications

- Optical switch, Infrared Cameras, Thermal Imaging Cameras

- Ophthalmology Equipment,Laser Vision Correction, Spectrometer

| Model | Dimension(㎜) | DC resistance | Peak Torque(N・m) | Documents/Drawings | ||

|---|---|---|---|---|---|---|

| 5V | 12V | 24V | ||||

| RSR10/15-S | φ10.5×20 | 13Ω | 0.0006 | 0.0013 | - | |

Power−Saving/Low−Heat type Rotary solenoidsRSU14 Series

- Externally built coil reduces heat generation.

- Most popular model due to wide range of uses.

- High torque and fast response time.

Applications

- Bank Note and Coin distribution driving force for Financial Terminal Equipment(ATMs, change machines, bank note counters).

- Shutter movement driving force for optical equipment (fundus cameras, surveillance equipment, spectroscopes)

- Sorting drive force for capsule (drug) quality control machines).

- Driving force for lowering/raising of props in amusement equipment.

- Driving force for opening/closing of door for coin payout units.

| Model | Dimension(㎜) | DC resistance | Peak Torque(N・m) | Documents/Drawings | ||

|---|---|---|---|---|---|---|

| 5V | 12V | 24V | ||||

| RSU14/10-SAP1-T115 | 29×25×23 | 115Ω | 0.02 | 0.024 | 0.029 | |

| RSU14/10-WAP1-T115 | 29×25×23 | 115Ω | 0.02 | 0.022 | 0.027 | |

High Durability type Rotary solenoidsRSR14 Series

- Long life-cycle with use of shaft bearing.

- High torque and fast response times.

Applications

- High Speed Shutter for Optical Equipment(fundus cameras, surveillance equipment).

- Driving force for distance adjustment of thread skipping in automatic looms.

- Driving force for postal mail sorting machines.

- Sorting drive force for capsule (drug) quality control machines).

- Vibration mechanism of arcade shooting game guns.

| Model | Dimension(㎜) | DC resistance | Peak Torque(N・m) | Documents/Drawings | ||

|---|---|---|---|---|---|---|

| 5V | 12V | 24V | ||||

| RSR14/10-CAB0 | φ26×31 | 15.6Ω | 0.022 | 0.036 | 0.049 | |

| RSR14/10-PAP0-G015 | φ26×31 | 15.6Ω | 0.012 | 0.023 | 0.033 | |

| RSR14/20-CT2 | φ26×61 | 20Ω | 0.04 | 0.061 | 0.096 | |

| RSR14/20-CBB0-N032A | φ26×44 | 32Ω | 0.032 | 0.043 | 0.082 | |

Standard type Rotary solenoidsRSR20 Series

- The most generic type used as a high-speed actuator for various purposes inside factory automation systems and labor-saving equipment.

- High-power, high-responsiveness achieved by our original technology including multi-layered yoke and high-power rare-earth magnet.

- This most generic series are used as a high-speed mechanical drive in a wide range of applications in various labor-saving equipment and automated machinery.

Applications

- Labor-saving equipment, Automated machinery

- Letter sorting machine, Automated textile machines

- Amusement Machines

| Model | Dimension(㎜) | DC resistance | Peak Torque(N・m) | Documents/Drawings | ||

|---|---|---|---|---|---|---|

| 5V | 12V | 24V | ||||

| RSR20/10-CAB0 | φ50×35 | 15Ω | 0.04 | 0.07 | 0.12 | |

| RSR20/20-CAB0 | φ50×45 | 6.2Ω | 0.07 | 0.18 | 0.23 | |

| RSR20/40-CAB0-N036 | φ50×65 | 36Ω | - | 0.17 | 0.25 | |

Large type Rotary solenoidsRSR80 Series

- Large rotary solenoids for factory automation and conveying equipment.

- It has high enough torque which can also be an alternative to air driven actuators which will free you from air source issues.

Applications

- Factory automation equipment

- Sorting System

| Model | Dimension(㎜) | DC resistance | Peak Torque(N・m) | Documents/Drawings | ||

|---|---|---|---|---|---|---|

| 5V | 12V | 24V | ||||

| RSR80/80-CAB0 | φ80×90 | 6Ω | - | 1.2 | 1.9 | |

Rotary Solenoids with Built−In StopsRSE32/47-C Serie

- This model has built-in end stops with the operating angle of 20°

- High holding force(Non-Excited Holding Force 0.015N・m)

- It can be easily installed with a single screw.

Applications

- Driving force for high speed sorting machines.

- Bank Note and Coin distribution driving force for Financial Terminal Equipment(ATMs, change machines, bank note counters).

| Model | Dimension(㎜) | DC resistance | Peak Torque(N・m) | Operating Angle |

Documents/Drawings | ||

|---|---|---|---|---|---|---|---|

| 5V | 12V | 24V | |||||

| RSE32/47-C020 | 46.5×32×16 | 20Ω | - | - | 0.02 | 20° | |

| RSE32/47-C038 | 46.5×32×16 | 38Ω | - | - | 0.02 | 20° | |

Rotary Solenoids with Built−In StopsRSF26/20 Series

- Has a built-in stopper so there is no need to make an external stopper.

- Compact Model.

- High Holding Torque (De-energized holding torque 0.01N・m).

Applications

- Operation of High Speed Shutters in Optical Equipment.

- Driving force for high speed sorting machines.

- Driving force for endoscope filter switching.

- Bank Note and Coin distribution driving force for Financial Terminal Equipment(ATMs, change machines, bank note counters)

| Model | Dimension(㎜) | DC resistance | Peak Torque(N・m) | Operating Angle |

Documents/Drawings | ||

|---|---|---|---|---|---|---|---|

| 5V | 12V | 24V | |||||

| RSF26/20-CS38-G020 | φ26×20 | 20Ω | - | - | 0.002 | 37.5° | |

Rotary Solenoids with Return Spring RSR28-SR/SL Series

- Reduced energizing time, low power consumption, low heat generation.

- Variable Operating Angles possible from 25/35/45°.

- Long life cycle due to reduced thrust motion of the rotating shaft.

Applications

- Operation of High Speed Shutters in Optical Equipment.

- Operation of Shutters in fundus cameras, surveillance equipment.

| Model | Dimension(㎜) | DC resistance | Peak Torque(N・m) | Operating Angle |

Documents/Drawings | ||

|---|---|---|---|---|---|---|---|

| 5V | 12V | 24V | |||||

| RSR28/17-SR | φ28×20 | 27.5Ω | - | 0.0052 | - | 25° 35° 45° |

|

| φ28×20 | 110Ω | - | - | 0.0052 | |||

| RSR28/17-SL | φ28×20 | 27.5Ω | - | 0.0052 | - | 25° 35° 45° |

|

| φ28×20 | 110Ω | - | - | 0.0052 | |||

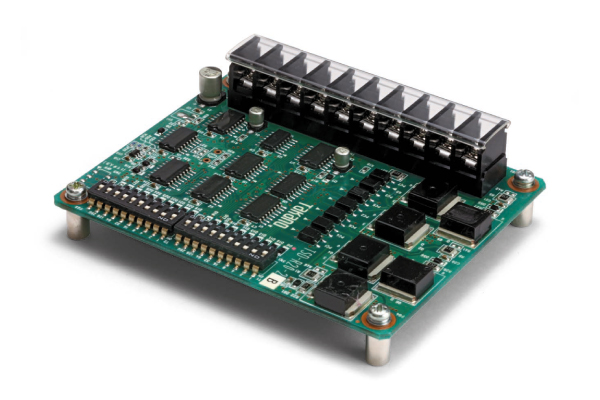

Driver board for rotary solenoidsTSD Series

- Rotary solenoid driver board which enables flexible setting of energization time in 1 msec step within the range of 1 to 511 msec for clockwise and counterclockwise rotation.

| Model | Dimension(mm) | DC resistance | Peak Torque(N・m) | Documents/Drawings | ||

|---|---|---|---|---|---|---|

| 5V | 12V | 24V | ||||

| TSD-R20-2B | 80×100×33 | 7.2Ω | - | - | - | |

注)External stops

Except for some models, to provide flexibility of travel angel, Takano bistable rotary solenoids have no built-in stops.

Therefore, external stops must be additionally set to mechanically define the traveling angle. Use rubber or similar buffer material for the stops. Avoid the use of metal stops that causes strong metal-to-metal impact which may lead to failure of the solenoid.

Series list

| Model | DC resistance | Dimension (Unit:mm) |

Peak Torque(Unit:N・m) | ||

|---|---|---|---|---|---|

| 5V | 12V | 24V | |||

| RSF22/08-O035 | 35Ω | φ22 × 8 | 0.0017 | - | - |

| RSR28/17-CAB0 | 8Ω | φ28 × 17 | 0.013 | 0.024 | - |

| RSR7/10-T010 | 9.5Ω | φ7 × 10 | 0.00045 | - | - |

| RSR10/15-S | 13Ω | φ10.5 × 20 | 0.0006 | 0.0013 | - |

| RSU14/10-SAP1-T115 | 115Ω | 29 × 25 × 23 | 0.02 | 0.024 | 0.029 |

| RSU14/10-WAP1-T115 | 115Ω | 29 × 25 × 23 | 0.02 | 0.022 | 0.027 |

| RSU14/10-CAP1-G014V | 13.5Ω | 29 × 25 × 23 | 0.024 | 0.042 | 0.064 |

| RSR14/10-CAB0 | 15.6Ω | φ26 × 31 | 0.022 | 0.036 | 0.049 |

| RSR14/10-PAP0-G015 | 15.6Ω | φ26 × 31 | 0.012 | 0.023 | 0.033 |

| RSR14/20-CT2 | 20Ω | φ26 × 61 | 0.04 | 0.061 | 0.096 |

| RSR14/20-CBB0-N032A | 32Ω | φ26 × 44 | 0.032 | 0.043 | 0.082 |

| RSR20/10-CAB0 | 15Ω | φ50 × 35 | 0.04 | 0.07 | 0.12 |

| RSR20/20-CAB0 | 6.2Ω | φ50 × 45 | 0.07 | 0.18 | 0.23 |

| RSR20/40-CAB0-N036 | 36Ω | φ50 × 65 | - | 0.17 | 0.25 |

| RSR80/80-CAB0 | 6Ω | φ80 × 90 | - | 1.2 | 1.9 |

| RSE32/47-C020 | 20Ω | 46.5 × 32 × 16 | - | - | 0.02 |

| RSE32/47-C038 |

38Ω |

46.5 × 32 × 16 | - | - | 0.02 |

| RSF26/20-CS38-G020 | 20Ω | φ26×20 | - | - | 0.002 |

| RSR28/17-SR | 27.5Ω | φ28 × 20 | - | 0.0052 | - |

| RSR28/17-SR | 110Ω | φ28 × 20 | - | - | 0.0052 |

| RSR28/17-SL | 27.5Ω | φ28 × 20 | - | 0.0052 | - |

| RSR28/17-SL | 110Ω | φ28 × 20 | - | - | 0.0052 |

| TSD-R20-2B | - | 80 × 100 × 33 | - | - | - |

Please refer to each product page for detail specifications.

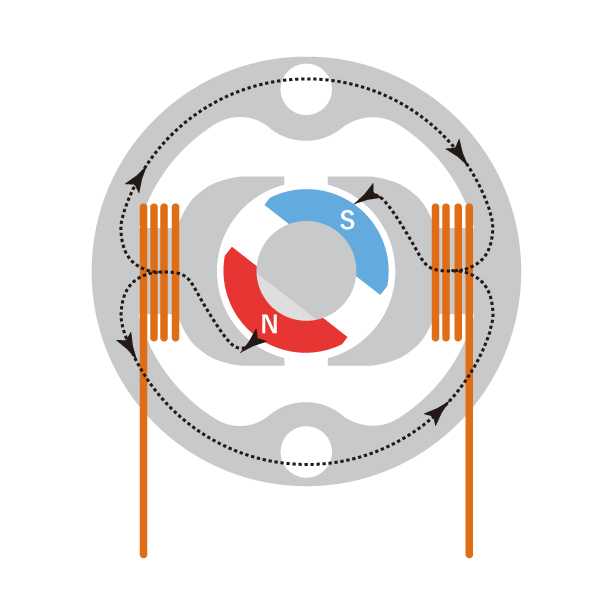

Structure and Operating Principles

High torque and high speed response within a constant operating angle.

Ideal for operations that reciprocate within an angle of 90° or less.

- A rotary solenoid is a rotary actuator designed specifically for reciprocating motion.

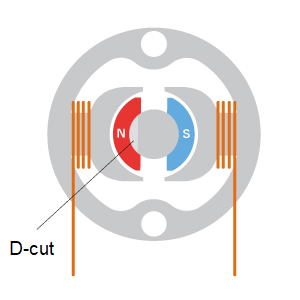

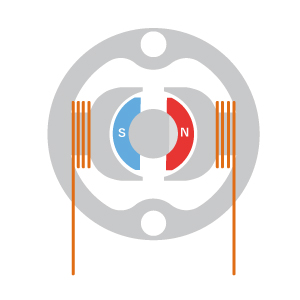

- Our rotary solenoid consists of two yokes on the fixed side, a coil, and a movable rotor part with a permanent magnet. By switching the electrical current direction of the coil, the N / S on the coil side is switched. The permanent magnet of the rotor repels the N / S on the coil side, causing reciprocating operation.

- Although it cannot rotate like a general motor, it has higher torque, higher response, and is superior than any motor of the same size in reciprocating movement within a certain angle.

De-energized Holding Power/Low Power Consumption.

The retention torque can hold the position at no longer electrification. Power-saving because it can be designed to lower the energization rate.

- The permanent magnet creates a magnetic field from the N pole to the S pole when de-energized. Therefore, even at the time of non-energization, holding power is kept with the adsorption force of the permanent magnet to hold the set position.

- Able to operate with only starting current due to the lack of necessity of a holding current. Reduced temperature rise and power consumption.

- Please select a model according to the weight of your load.

Rotary solenoid operating principle video

How to use bi-stable solenoid

External stops

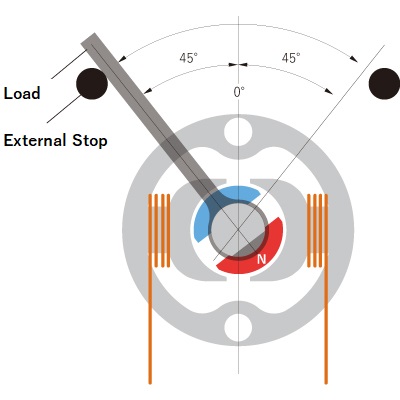

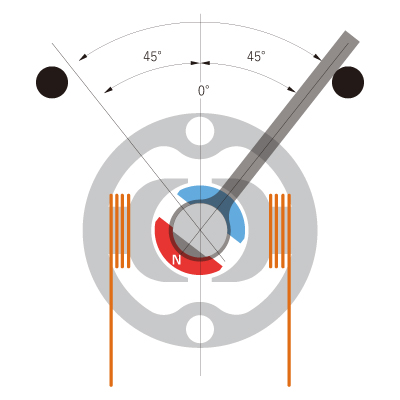

Except for some models, Takano bi-stable rotary solenoids have no built-in stops.

Therefore, external stops must be set separately to mechanically define the travel angle.

In this case, use rubber or similar buffer material for the stop. Avoid the use of metal stops that causes strong metal-to-metal impact which may lead to failure of the solenoid.

【How to set external stops】

-

When Takano bi-stable rotary solenoids are delivered (which no stops are equipped), physical relation between the magnet and the shaft D-cut is as shown in Fig. A) or B) below. The state is magnetically balanced and stable.

(A)

(B)

-

Before use, turn the shaft D-cut from the as-delivered stable position and then set external stops. In standard, the center point of rotation and the center between stops are 0° as shown in each product drawings.

The practical rotation range is up to ± 45° from the center point (total travel angle of up to 90°). Set the external stops within this range.

Practical Rotation Range 90°

Practical Rotation Range 90°

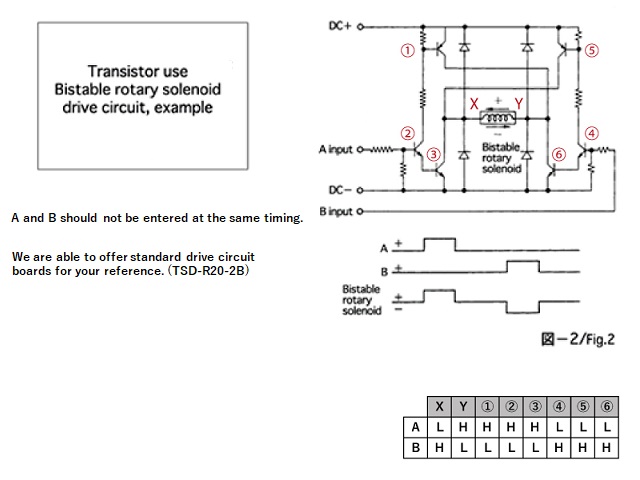

Bi-stable drive circuit

To rotate bi-stable rotary solenoid from one end to the other and return, polarity of energization(+/-) needs to be switched.

Fig. 2 shows a typical drive circuit diagram for your reference.

We also provide a driver board as an option for operating our solenoids.