Electromagnetic Actuator Technology Column: From Basics to Latest Trends.

What is an ultrasonic oxygen sensor? — A non-contact and maintenance-free oxygen concentration measurement technology

2.Reasons for Utilizing "Ultrasound" in Oxygen Sensors

3.Principles of the Ultrasonic Oxygen Sensor

4.Comparison with Zirconia and Galvanic Cell Type Sensors

5.Characteristics of the Ultrasonic Oxygen Sensor

1.Introduction

"Maintenance can be troublesome, and it requires both time and cost..."

In medical and industrial settings, many professionals are faced with challenges such as the regular replacement and calibration of sensors, as well as measurement drift, when measuring oxygen concentration.

If you could be freed from such hassles and frustrations and continue an accurate and stable measurement over a long period, what would you think? In recent years, a promising solution has gained attention: the ultrasonic-based physical oxygen sensor.

This column explains, in a clear and accessible manner, why the ultrasonic method can overcome the challenges of conventional methods, from its principles to its specific advantages.

2.Reasons for Utilizing "Ultrasound" in Oxygen Sensors

When the topic is sensors for measuring oxygen concentration, chemical methods such as zirconia and galvanic cell type have been conventional. However, these methods are accompanied by challenges such as periodic replacements, drift, and delayed response.

Consequently, one technology that has been gaining attention in recent years is the method of measuring oxygen concentration using ultrasound!

This method is a physical measurement technique for determining oxygen concentration by utilizing the difference in the speed of sound in gases, without relying on chemical reactions, and is characterized by non-contact, long lifespan, and high-speed responsiveness.

3.Principles of the Ultrasonic Oxygen Sensor

Ultrasonic oxygen sensors work based on a fundamental physical principle: the speed of sound travels differently through gases of different compositions.

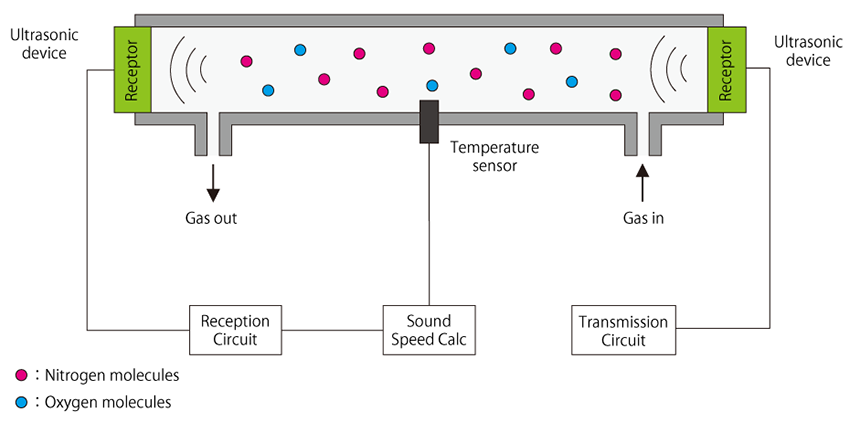

Specifically, the sensor is configured with the transmitter and receiver positioned to face each other. Ultrasound is emitted from the transmitter towards the target gas being measured, and the time required for the ultrasound to travel a certain distance (propagation time) is measured. By analyzing the speed of sound, the oxygen concentration is calculated. For instance, the speed of sound in air is approximately 343 m/s (at 20°C); however, as the proportion of oxygen increases, the molecular weight changes, and accordingly, the speed of sound varies as well. By accurately capturing these minute changes, it becomes possible to measure oxygen concentration in a non-contact and real-time manner.

Principle of Ultrasonic Oxygen Sensor

4.Comparison with Zirconia and Galvanic Cell Type Sensors

| Sensor method | Features | Drawback |

|---|---|---|

| Ultrasonic type | Non-contact, long lifespan, rapid response, capable of simultaneously measuring flow rate | The initial cost is somewhat high. |

| Zirconia type | It can be used even at high temperatures and is highly reactive. | Zero point calibration is required, warm-up time is necessary, and it is expensive. |

| Galvanic cell type | Compact and affordable. | Regular replacement is essential, and the lifespan is short. |

In this manner, the ultrasonic method does not utilize chemical reactions, enabling long lifespan, low maintenance, and real-time measurement, effectively addressing the challenges of conventional methods. It is highly effective even in fields such as healthcare, food, and industrial gases, where frequent replacement is challenging.

5.Characteristics of the Ultrasonic Oxygen Sensor

1.High-speed response and real-time measurement

Due to its physical measurement method, it can output concentrations in real-time with minimal delay. It is also highly capable of detecting sudden changes.

2.Non-contact type

Due to the structure where the gas does not directly contact the sensor, concerns about corrosion and deterioration are minimal, ensuring long service life.

3.Maintaining accuracy even under mixed gas conditions.

In order to conduct analysis based on the difference in sound velocity, it is possible to precisely extract fluctuations in oxygen concentration even when mixed with other gases such as carbon dioxide and nitrogen.

6.Main Application Examples of the Ultrasonic Oxygen Sensor

- Oxygen monitoring in medical settings

- Management of oxygen concentration in industrial gas mixing equipment

- Safety surveillance in enclosed spaces such as warehouses and storage rooms

- Control of oxygen supply in fermentation processes

The ultrasonic oxygen sensor provides significant technical advantages to customers that have been struggling with the maintenance of oxygen sensors.

7.Summary

The ultrasonic oxygen sensor is a novel technology that measures oxygen concentration physically and non-invasively. Since it does not utilize chemical reactions, it offers minimal drift, long life, and highly reliable sensing. This sensor is expected to provide a new option in scenarios where real-time monitoring of oxygen concentration or long-term operation is required. I sincerely hope that this column serves as an opportunity for you to learn about the potential of ultrasonic oxygen concentration measurement.

8.Product Information and Inquiries

Takano offers ultrasonic products such as:

- Ultrasonic oxygen sensors (concentration measurement)

- Ultrasonic flow controllers (capable of both concentration measurement and flow control with a single device).

If you are considering purchasing, please refer to the details at the link below or feel free to contact us.