Electromagnetic Actuator Technology Column: From Basics to the Latest Trends

Column

What is the "ultra-high-speed and high-durability" technology that changes the common understanding of rotary solenoids? Solenoid applications with a 5ms response time and durability of 100 million cycles.

1.Introduction: Evolving Solenoid Technology

"In stepping motors, there is concern about losing synchronization."

"With general rotary solenoids, the lifespan is short and maintenance is challenging."

In modern industrial machinery development, challenges with such actuators are endless. There is a growing demand for drive components that are faster, more accurate, and longer-lasting.

Takano, after years of research and development, has developed a solenoid that combines "ultra-high-speed drive with less than 5ms response time*" and "durability exceeding 100 million cycles*."

Among rotary solenoids, Takano's technology (bistable rotary system) excels in performance and reliability. This document provides a detailed explanation from basic principles to comparisons with other systems.

2.Basic Principles of the Bistable Rotary Solenoid

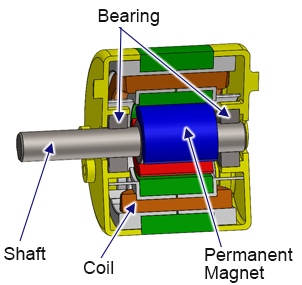

The rotary solenoid (bistable rotary type) is an actuator specialized in reciprocating rotary motion at a limited angle using electromagnetic force. When current is applied to the coil, the magnetic poles of the stator change, causing rotational motion through the attraction and repulsion forces generated between the rotor’s permanent magnet and the stator.

3.High-Speed Technology (Stepping Motor vs. Bistable Rotary Solenoid)

The rotary solenoid (bistable rotary type) shares common characteristics with the stepper motor in that it converts electrical energy into rotational motion centered around a shaft (axis).

However, driving a stepping motor involves a method where the rotor is "attracted" following the excitation pulses, making it prone to step-out (loss of synchronization) during high-speed and rapid acceleration operations. Consequently, it is challenging to achieve operation with a response time on the order of a few milliseconds.

On the other hand, a rotary solenoid, with a bistable directional rotary mechanism, does not require position control, operates by instantly applying maximum power, and stops at a predetermined position using a mechanical stopper. Therefore, it can achieve high-speed response on the order of a few milliseconds.

| Stepping motor | Bistable rotary solenoid | |

|---|---|---|

| Time response | Several tens to hundreds of milliseconds are common. | Several milliseconds to tens of milliseconds. |

| Loss of synchronism risk | Likely to occur during high-speed operation. | None. |

| Operation | Continuous rotation, precise positioning over a wide range. | Short strokes, high-speed reciprocating motion between two points, instant switching. |

4.High-Durability Technology (Differences from a typical rotary solenoid)

Do you have the impression that rotary solenoids have a short lifespan? In fact, durability changes dramatically depending on the structure. Here, we compare a general rotary solenoid (linear conversion type) and Takano's rotary solenoid (bistable rotary method).

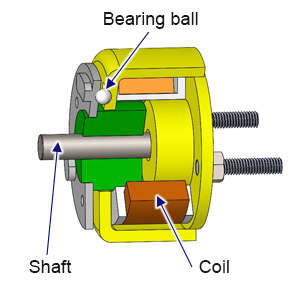

General rotary solenoid (linear conversion type)

The principle of the linear solenoid is applied to convert the suction force generated by electrification into rotational motion using bearing balls and special ball grooves (race).

Due to its structure, the ball grooves and bearing balls are always in contact, sliding against each other with strong force, making wear and wear debris more likely to occur with each operation.

As a result, malfunctions are prone to happen, and the durability is generally said to be limited to about 10 million to 50 million cycles.

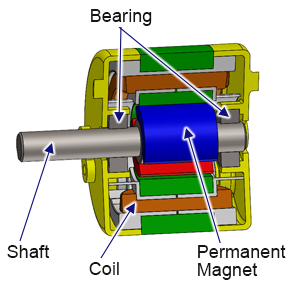

Takano's rotary solenoid (bistable rotary type)

The rotor shaft is supported solely by bearings and rotates in a pure rotational structure. Since there are no contact points that wear out other than the bearing section, the generation of wear particles can be minimized to the extreme. Its lifespan depends on the bearings, making it possible to achieve durability exceeding 100 million cycles without maintenance.Since the lifespan depends on the bearings, we have confirmed maintenance-free operation exceeding 100 million cycles under our specified test conditions.

Standard rotary solenoid

(linear motion conversion type)

Takano's rotary solenoid

(bistable rotary type)

5.Application Examples

Takano's rotary solenoid (bistable rotary type) is utilized in a wide range of fields including transport equipment, ATMs, automated robots, aerospace-related equipment, automatic looms, medical devices, and shutter mechanisms of optical equipment. Among them, the solenoid for automatic looms maximizes its high-speed and high-durability performance. Automatic looms operate under the following harsh conditions:

- Continuous operation: Running continuously at 1,200 times per minute (1,200 rpm), 24 hours a day, 365 days a year without rest

- High-speed operation: The weft is continuously transported at approximately 300 kilometers per hour

The role of the bistable rotary solenoid in an automatic loom

The bistable rotary solenoid plays a critical role in controlling the actions of "launching, stopping, cutting, and loosening" the thread. To reliably control the weft yarn transported at speeds of approximately 300 km/h, high-speed response within a few milliseconds is essential. Furthermore, assuming two years of maintenance-free continuous operation, it requires high durability to withstand over a billion repetitive operations.

6.Conclusion

Takano's rotary solenoid (bistable rotary type) combines ultra-fast response under 5ms* and high durability of over 100 million cycles* with bearing-supported shafts, meeting the demanding requirements of modern industrial machinery. Takano's rotary solenoids aim to assist your projects by addressing challenges related to speed enhancement and extended lifespan in design, as well as ensuring stable operation under harsh conditions.

We have also prepared a page summarizing the principles and selection guide for the bistable rotary solenoid, which could not be fully covered in this column! Please take a look!

*The numerical values and maintenance-free frequency mentioned are actual measurements under our specified test conditions. They may vary depending on the actual operating environment (load, voltage, mounting direction, etc.), so please refer to the product specifications for more details.