Solenoid Valves for medial devices

Compact 2-Way/3-Way Solenoid Valves for Chemical Liquids

Product introduction

-

Smooth flow prevents chemical contamination.

Diaphragm type direct-operated-poppet-valve structure of Takano Solenoid Valves simplifies the internal structure of the valve chest inside. This allows smooth flow of the liquid and prevents chemical residue which becomes the cause of chemical contamination.

-

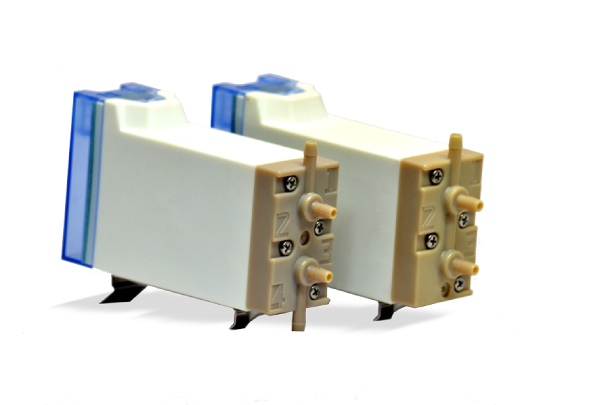

It's flat and slim. Multiple units can be set in limited space.

One of the unique features is their shape. Being flat and slim, multiple valves can be set in parallel in limited space.

-

Compatible with various types of chemicals.

Takano Solenoid Valves employ resin and rubber materials with high chemical and corrosive resistance for the wetted parts. This enables to be compatible with wide range of chemicals and applications.

-

Custom design to your unique requirements.

In addition to the standard lineups, we appreciate to offer custom products to your unique requirements in shape, characteristics, etc.

Series Comparative Table

Independent Control Linear Flow 2 Way/3 Way Solenoid ValveW13 Series

- Individual solenoids and valves on each side to allow independent flow control.

- Low-voltage rotations of solenoid arm for power consumption.

- Reduction of heat transfer to chemical liquids.

- Oil-Free, Metal-Free. Only PEEK and FKM utilized for wet parts.

Applications

- Opening, closing and switching of valves in blood cell counter flow path.

- Reagent Control Valve for Chemical Analyzing Machines.

| Model | Valve Operation |

Rated Voltage |

Number of Ports |

Operating pressure range |

Orifice Diameter |

Cv (Water) |

Documents/Drawings |

|---|---|---|---|---|---|---|---|

| W13X-25A | NC | 24VDC | 2×2 | -75~250 (kPaG) |

1.3 | 0.03 | |

| W13X-35A | NC | 24VDC | 3 | -75~250 (kPaG) |

1.3 | 0.03 |

Pinch valve

Product introduction

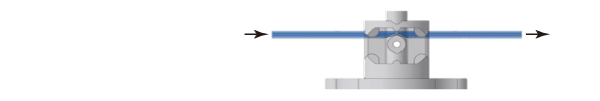

A pinch valve is a valve that opens and closes the flow path of liquids by pinching the rubber tubing. Since the liquid material does not flow through the valve body, it does not accumulate liquid in the valve and is suitable for hygienically controlling flow of liquid chemicals.

-

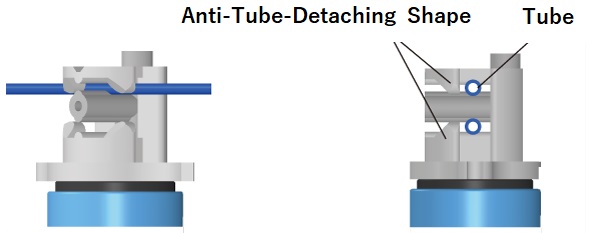

Integrated Tube Stopping Mechanism

Since the tube stopping mechanism is integrated into the valve body, there is no need to install an external tube stopping mechanism.

-

Low Power Consumption, Low Temperature

The energy consumption and heat generated while operating is greatly suppressed by our original magnetic circuit design.

-

Lead Wire Outlet

The lead wire is designed under the surface of the main body, making it stress-free to install the valve.

Pinch ValvesTPV Series

Applications

- Opening, closing and switching of valves in blood cell counter flow path.

- Reagent Control Valve for Chemical Analyzing Machines.

- Liquid flow control, including slurries.

| Model | Outer Dimensions |

Working Voltage |

Operating pressure range |

Compatible Tube Diameter |

Documents/Drawings |

|---|---|---|---|---|---|

| TPV-N040 | φ26×57 (㎜) |

12VDC | 0~150 (kPaG) |

O.D. 3/I.D. 1 (㎜) |

|

| TPV-N160 | φ26×57 (㎜) |

12VDC | 0~150 (kPaG) |

O.D. 3/I.D. 1 (㎜) |

Product Feature

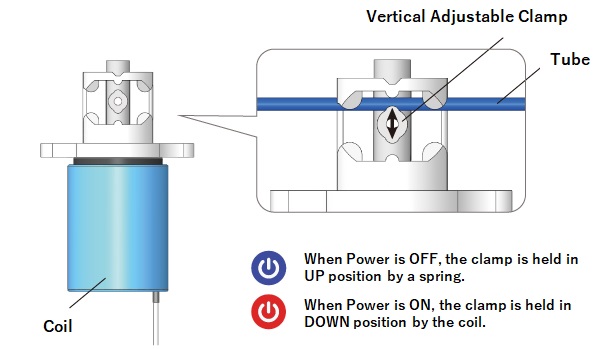

Direct flow by pinching or releasing the tube.

Since the liquid does not flow through the valve, it is hygienic and suppresses the risk of cross-contamination.

Multi-Purpose

The flow control method can be freely adjusted by changing the mounting position of the tube.

N.C. Type

Tube mounted above pinch clamp.

N.O Type

Tube mounted below pinch clamp.

3-Way Type

Tubes mounted above and below pinch clamp.

Tube Stopping Mechanism

Easy mounting and removal of tubes while keeping the tube in use secure with stoppers.