Step Rotary Solenoid

Product introduction

Takano Step Rotary Solenoids apply the fundamental structure of Bi-stable rotary solenoid with additional magnetic poles to enable multi-positional control. Similar to bi-stable rotary solenoid, the forces of attraction and repulsion between the permanent magnet of the rotor and the magnetic pole generated in the yoke induce rotational (step) motion for rapid switching between multiple positions.

-

Capable of multi-position control

Up to 12-position control in increments of 30° and up to 6-position control in increments of 60°, depending on the energization method.

-

No external stops required

These step solenoids need no external stopper because they stay in position using the holding force of the permanent magnet even during the de-energized state.

-

High torque

High torque enables direct drive.

-

Noise-free

Operates with no external stopper which frees you from the impact noise caused when the load hits the stopper.

-

Long life and high-reliability design

Because there is no stopper that generates impact and the only parts that actuate is the ball bearing, this Step Solenoid is long life and highly reliable.

-

Absolute position control

Because of absolute position control, there is no step-out such seen on stepper motors.

Series list

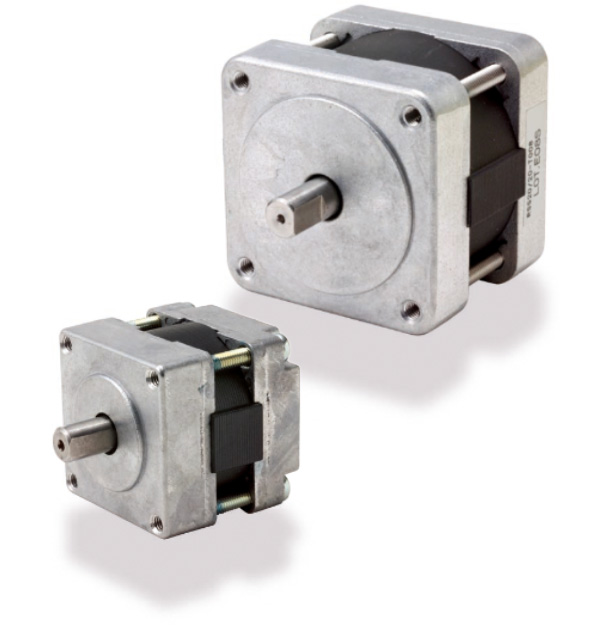

Compact type Step Rotary SolenoidsRSS14 Series

- Compact Type:30×30×30mm

- Bi-directional switching is possible.

- Absolute position control.

- Operates with low noise.

- High durability due to the absence of stoppers.

Applications

- Drive force for shutters in medical units.

- Drive force for shutters in light source units.

| Model | Dimension (㎜) |

Operating Angle | Non-Excited Holding Force (N・m) |

Torque when Excited (N・m) |

Documents/Drawings |

|---|---|---|---|---|---|

| RSS14/10-CAB0 | 30×30×30 | 30°/60° | 0.008 | 0.02 |

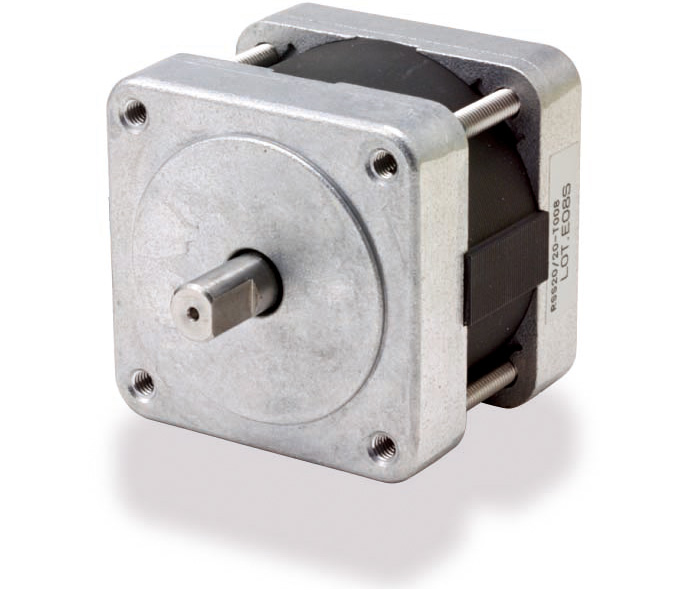

High Torque Type Step Rotary solenoidsRSS20 Series

- High Torque Type.

- Bi-directional switching is possible.

- Absolute position control.

- Operates with low noise.

- High durability due to the absence of stoppers.

Applications

- 2-Way/3-Way Switching Drive Force, Drive force for automated ticket gate sorting units.

- Logistic/Transport Machine Drive Force Unit

| Model | Dimension (㎜) |

Operating Angle | Non-Excited Holding Force (N・m) |

Torque when Excited (N・m) |

Documents/Drawings |

|---|---|---|---|---|---|

| RSS20/20-T008 | 50×50×43 | 30°/60° | 0.025 | 0.088 |

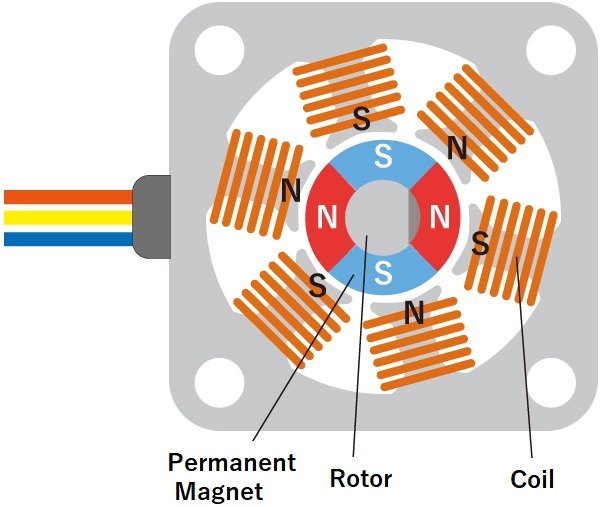

Structure and Operating principles

Multi-position control

- Takano Step Rotary Solenoids apply the fundamental structure of bi-stable rotary solenoid with additional magnetic poles to enable multi-positional control.

- It consists of a rotor section on the moveable side with four permanent magnets and six coils on the stationary side, and switches the N/S of the coil side. The rotor's permanent magnets repel the N/S of the coil side, causing rotational motion.

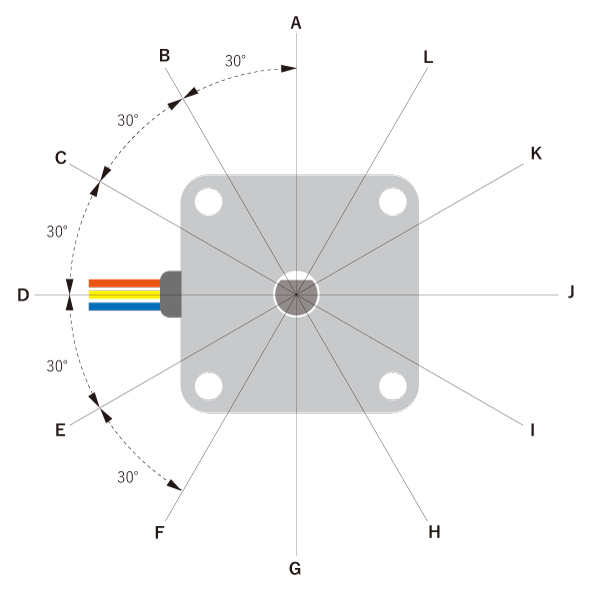

- Up to 12-position control in increments of 30˚ and up to 6-position control in increments of 60˚ depending on the lead line connection pattern.

- Built-in permanent magnet holds our step solenoids in the position of your choosing, even when power is turned off.

Driving Force Method

Control Position and Energization Method

- The solenoid can be driven by following the hard wire patterns listed on the hard wire pattern control chart. To move it to the A position, connect the red lead to (+), yellow lead to (-) and keep the blue line (open). From the A position, connect the red lead to (+), yellow lead (open), blue lead (-) to change the angle 30°.

- For 60° Increment operation, please reference the 60° hard wire pattern control chart.