Electromagnets

Product introduction

Takano Electromagnets consist of an iron core and a coil to attract magnetic substances, using the magnetic action induced by electric current, only while the current is applied.

This compact functional devise offers high power with high reliability.

The structure and design to release the residual magnetism left after de-energization is also one of its unique features.

-

Our DC-powered electromagnet generates magnetic field of high-power with high efficiency

This highly efficient electromagnet generates a magnetic field of a strong pull (high attractive force) with low energy consumption.

You can adjust to desired attractive force by changing the power applied and the magnetic gap between the electromagnet and the substance.

-

Minimized in residual magnetic

When an electromagnet is energized, the problem is how to release the magnetic force which remains on the device after the power is turned off.

Our electromagnet is designed with measures to release and minimize this residual magnetic force.

-

Lightweight, compact design for space-saving

Compact mechanism with high reliability.

-

Long life

High mechanical strength and excellent durability.

-

For custom-made requirements

We also supply custom-made electromagnets with higher power, original dimensions,etc to satisfy your unique requirements.

Series Comparative Table

Thin/Lightweight ElectromagnetsTMH-3015

- Strong holding power of 170N adsorption.

- Thin and lightweight, ideal for installation in tight spaces.

- Low residual magnetism design for fast breakaway.

Applications.

- Automatic wetted parts equipment zipper.

- Magnetic Robot Grippers.

- Adsorption and removal of metallic impurities.

- Runway change for conveyor machines.

| Model | Dimension(㎜) | DC resistance | Holding torque(N) | Documents/Drawings | |

|---|---|---|---|---|---|

| 12V DC | 24V DC | ||||

| TMH-3015 | φ30×15 | 56Ω | 90 | 170 | |

High Holding Power ElectromagnetsTMH-3029A

- Strong holding power of 60N adsorption.

- Low residual magnetism design for fast breakaway.

Applications

- Automatic wetted parts equipment zipper.

- Magnetic Robot Grippers.

- Adsorption and removal of metallic impurities.

- Runway change for conveyor machines.

- Minilab: Negative fixing unit drive.

| Model | Dimension(㎜) | DC resistance | Holding torque(N) | Documents/Drawings | |

|---|---|---|---|---|---|

| 12V DC | 24V DC | ||||

| TMH-3029A | φ30×29 | 56Ω | 50 | 60 | |

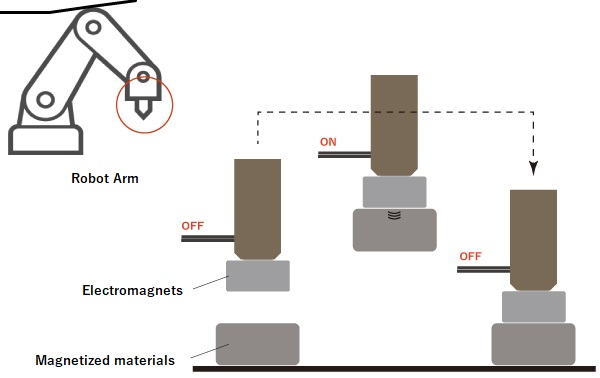

Example of use

Electro Magnetic Gripper for Robots

- Pulls in as the coil is energized. Stays in position using the magnetic force of the permanent magnet even after the coil is de-energized.

- With the electromagnet, objects can be easily attracted, moved, and detached by turning the power on and off.