Proportional Solenoid Valves

Product Introduction

Solenoid valve designed for applications that freely control the output flow rate. Flow rates from valve closed to valve fully open (0-100%) can be output proportional to the input current value unlike other electromagnetic valves.

Enables automation of flow rate adjustments.

It has been adopted in various fields such as for semiconductors, medical treatment, and general industrial equipment.

-

High Precision

High precision of the control current value enables highly accurate flow adjustment.

In addition, since the drive unit including the valve body is designed horizontally with no sliding parts, there is little turbulence in the flow rate and it has a long life cycle.

-

Manufactured in a Clean Room

The gas contact parts are oil-free and are manufactured in a clean room, so they are hygienic valves with reduced contaminants.

-

The piping connection method can be flexibly supported.

-

Customization Available

We will customize shape and specifications to your design.

Series Comparative Table

Ultra Compact Proportional Control Solenoid ValvePSV-01T

- Compact and lightweight design | 15.8×18×48mm, weight 70g

- Low seat leak specification

Applications

- Chromatographs, mass spectrometers, environmental gas measurement devices, life science devices, and other analytical instruments.

- Oxygen concentrators, Anesthesia machine, and Portable medical devices for flow and pressure control of oxygen.

| Model | Rated Voltage |

Valve operation |

CV (Air) |

Orifice Diameter (mm) |

Operating pressure differential (MPaG) |

Drawings |

|---|---|---|---|---|---|---|

| PSV-01T | 24V | Normally close (NC) |

0.03 | 1.2 |

~0.35 | - |

Compact Proportional Control Solenoid ValvesPSV-03T Series

- 18mm wide compact type that can be installed in tight spaces.

- The valve body is manufactured using PTFE.

- Body type and manifold type can be selected.

Applications

- Gas control valve for mass flow controllers.

- Anesthetic Machines/Respiratory Machines/Oxygen Concentrators/Gas Burners/Control valve for environmental/Measuring equipment.

| Model | Rated Voltage |

Valve Operation |

Cv (Air) |

Orifice size |

Standard Flow Rate |

Operating differential pressure range |

Drawings |

|---|---|---|---|---|---|---|---|

| PSV-03T-002 | 24VDC | NC | 0.007 | 0.7 (mm) |

2L/min | 0.05~0.5 (MPaG) |

|

| PSV-03T-005 | 24VDC | NC | 0.018 | 1.5 (mm) |

5L/min | 0.05~0.5 (MPaG) |

|

| PSV-03T-030 | 24VDC | NC | 0.109 | 3.6 (mm) |

30L/min | 0.1~0.3 (MPaG) |

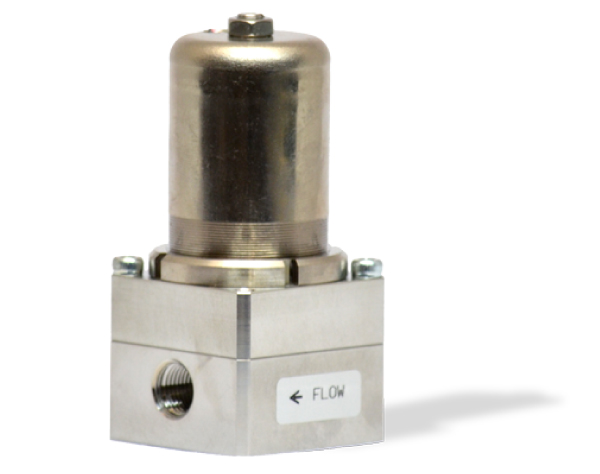

Compact High Flow Proportional Solenoid ValvePSV-200T Series

- Stable flow control is made possible by the use of a lateral structure that does not degrade the control resolution in high-pressure environments.

- Capable of 200L/min flow control despite its compact size.

Applications

- Gas control valve for mass flow controllers.

- Anesthetic Machines/Respiratory Machines/Oxygen Concentrators/Gas Burners/Control valve for environmental/Measuring equipment

| Model | Rated Voltage |

Valve Operation |

Cv (Air) |

Orifice size |

Standard Flow Rate |

Operating differential pressure range |

Drawings |

|---|---|---|---|---|---|---|---|

| PSV-212T | 12VDC | NC | 0.26 | 7.4 (mm) |

150L/min | 0.2~0.5 (MPaG) |

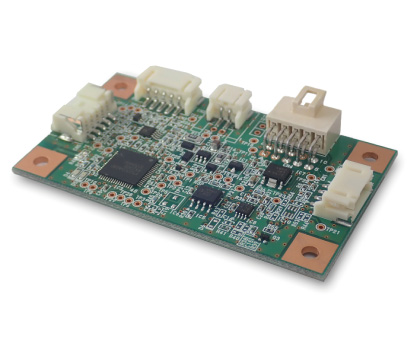

PCB for proportional valve control

- PWM control board dedicated to proportional control valves.

- Automatic flow control according to input signals is possible by connecting the proportional control valve and the sensor.

- Available in two types: a board type that can be compactly installed in a device and a type where the board is housed in a case.

Applications

- Proportional valves' PWM control for flow and pressure’s automatic control.

- Valve control for N2 purge.

| Model | Rated Voltage |

Standby power |

Interface | For valve | Usage temp |

Drawings |

|---|---|---|---|---|---|---|

| PBCS000 | DC12~24V | Less than 1W | Analog (0-5V) Digital (RS485) termination resistor: 120Ω |

PWM (8kHz) |

5~50℃ |

-

|

Product Features

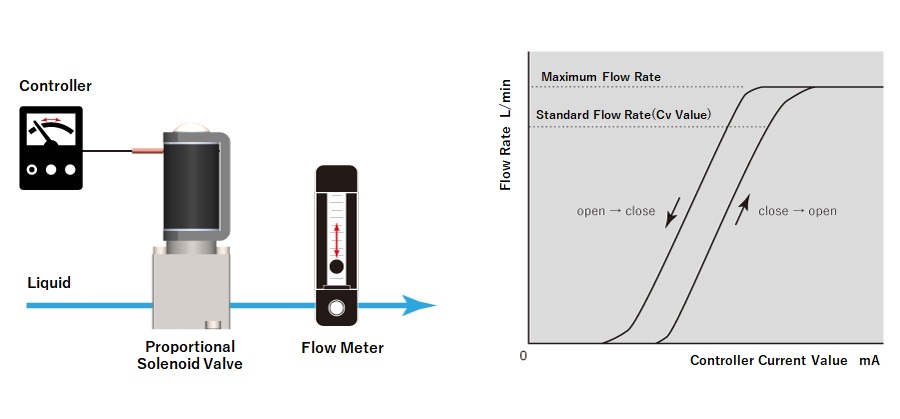

Outputs a flow rate proportional to the current

- By increasing or decreasing the current value of the controller, the flow rate can be adjusted steplessly.

- The Cv value is calculated at the standard flow rate, and the valve itself can output above the standard flow rate (maximum flow rate). Therefore, there is no need to worry about a decrease in the output flow rate during continuous use.

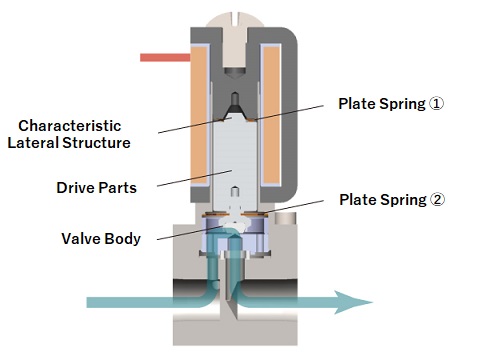

High-precision, long-lasting lateral construction with no sliding of the drive unit

- Since the drive unit containing the valve plug is supported vertically by plate springs ① and ②, there are no sliding parts. Therefore, there is no wobble or flow change during operation, and the valve has a long lifecycle since there is no deterioration caused by sliding.

- The patented high pull force lateral construction ensures stable proportional characteristics, allowing a large flow rate to be controlled with a small solenoid.

- The valve body is made of PTFE material for high corrosion resistance. In addition, the valve body does not stick to the valve seat, which occurs with rubber valve bodies, so the valve can be used stably.